Accredited according to DIN EN ISO / IEC 17025:2018 by the DAkkS accredited testing laboratory. The accreditation applies to the test methods listed in the certificate (indicated with *).

Services by testing groups

Know-how

The team of DIFK GmbH employees undergoes continuous development in mandatory training measures defined by the accreditation procedure according to DIN EN ISO/IEC 17025:2018. These training courses cover the quality-relevant workflow and, especially, the handling of all established and lately introduced measuring methods in high temperature processes.

Customer focus

We do not only give advice to our clients regarding the selection of appropriate measurement methods to solve their individual enquiry, but we also provide support during sample collection and specimen preparation. If necessary, we discuss the results of the completed measurements with our clients.

Fast processing

The results and test reports are made available to the customers within the shortest possible time periods, even in the case of comprehensive analyzes. By doing so, we help our customers to fulfil their commitments in due time.

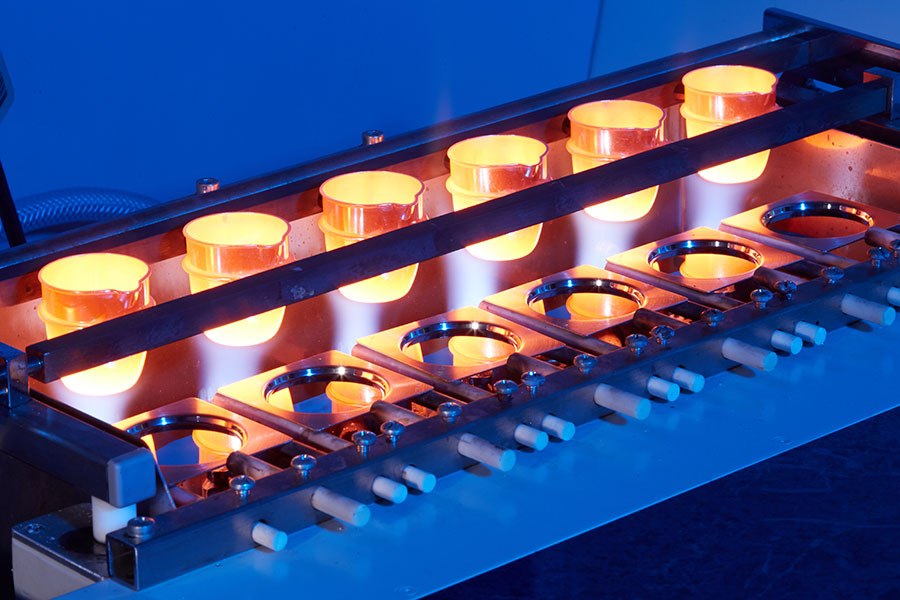

Service portfolio

DIFK GmbH uses state-of-the-art machinery and evaluation software based on pertinent provisions and testing standards. Consequently, we provide our customers with excellent results: maximum precision and reliable reproducibility. Thanks to our testing expertise in all four disciplines we deliver optimum productivity to realise the principle "Everything from a single source - all in one".

Reliability

The reliability of DIFK GmbH is ensured by a system of independently implemented measures, such as accreditation according to DIN EN ISO/IEC 17025:2018, external monitoring of all calibrations and adjustment of all measuring equipment, regular participation in collaborative trials with partners throughout Europe as well as external monitoring of all safety devices in the laboratories.